Hot line

Hotline - a system for collecting and processing information aimed at

timely detection and prevention of fraud, theft and corruption.

E-mail

hotline@rostec.ru

Feedback

For reports of corruption

Production automation

Radically improving labor efficiency and safety through the use of technologies with a high level of automation

Increasing the performance speed

Performing multiple tasks simultaneously

Reducing the number of errors

Your personal manager is just two clicks away from you

Automation systems types

Automation of assembly plants

Automated non-synchronous

assembly lines

High-performance assembly

machines

Automatic synchronous

assembly lines

Flexible (universal) assembly

centers

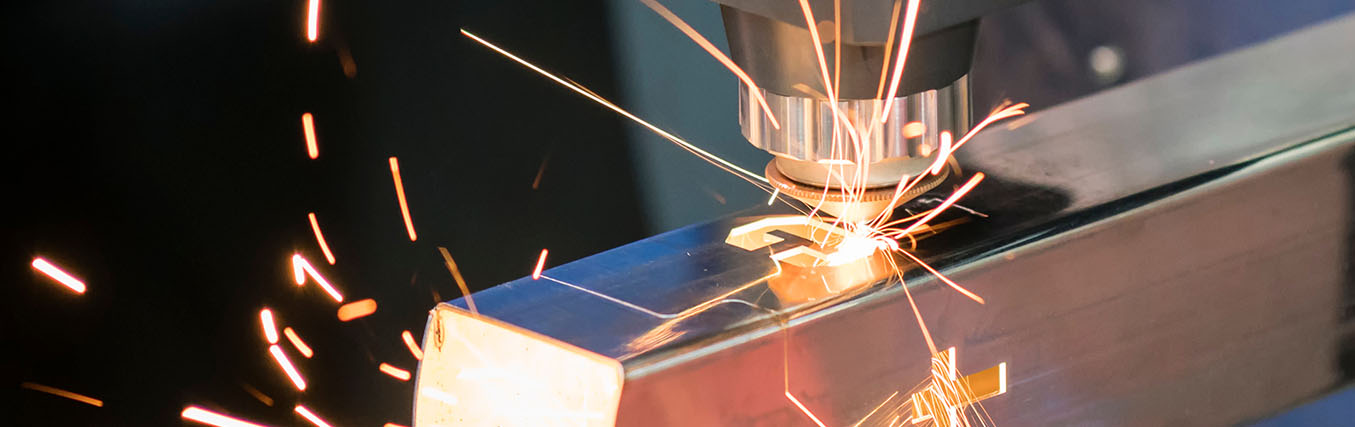

Automation of machining

industries

Development and production of

systems of accumulation,

orientation, supply and delivery

of billets, as well as systems of

inter-station transport.

Apply

Apply

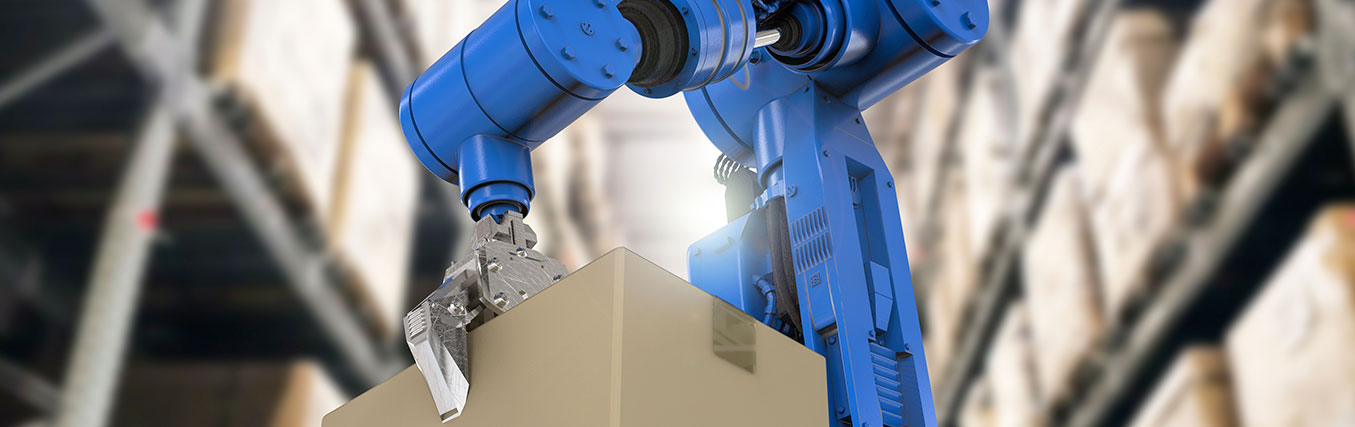

Automation of warehouse and

logistics processes

Development of systems of

automatic warehouses for raw

materials, materials, finished

products, as well as automatic

warehouses for storage and

delivery of replaceable

equipment and tools in the

flexible production systems.

APPLY

APPLY

Automation of hazardous and

highly hazardous industries

Development of technologies

and equipment aimed at

automation of various

technological processes of

hazardous and

industries.

Apply

Apply

Development of electro-vacuum

microwave devices

Development and production of

multipath klystrons to power

electron accelerators, which are

used in the following types of

equipment:

accelerators for inspection

complexes; accelerators for

medicine; accelerators for

materials processing.

Apply

Apply

Apply for cooperation

Fill in the form